RMCS Precast Lifting Loops and Clutches

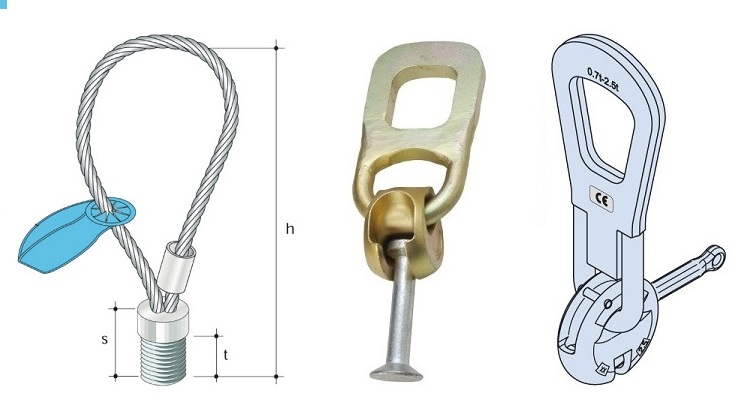

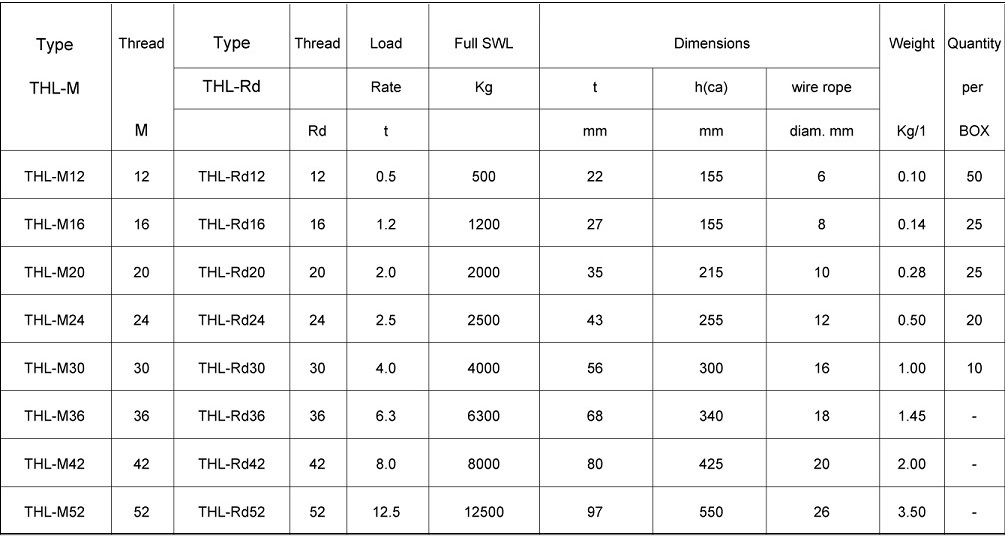

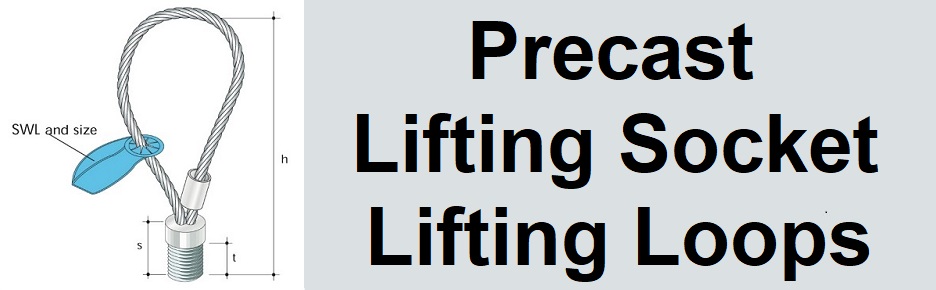

Threaded Lifting Loops can be used with all sizes of threaded inserts. They are the most economic lifting loops and are suitable for most applications. They are not suitable for turning/pitching. They may be reused subject to the inspection procedure, detailed below, but they are not recommended for severe reuse conditions. Threaded Lifting loops should only be attached to the unit after the concrete strength has reached 15 N/mm. In some cases it may be economical and practical to leave the loops attached to the unit, until final installation.

Threaded Lifting Loops are manufactured from high grade steel wire, swaged in a steel ferrule and finished with zinc plating. They are clearly marked with their SWL. The thread type is Rd/M, which is compatible with both metric and Rd inserts. Threaded Lifting Loops are suitable for use with inserts cast in flush with the face of the unit, or recessed by using the recess formers.

Lifting at an angle greater than 45 degrees is not allowed.

Lifting at an angle greater than 45 degrees is not allowed.

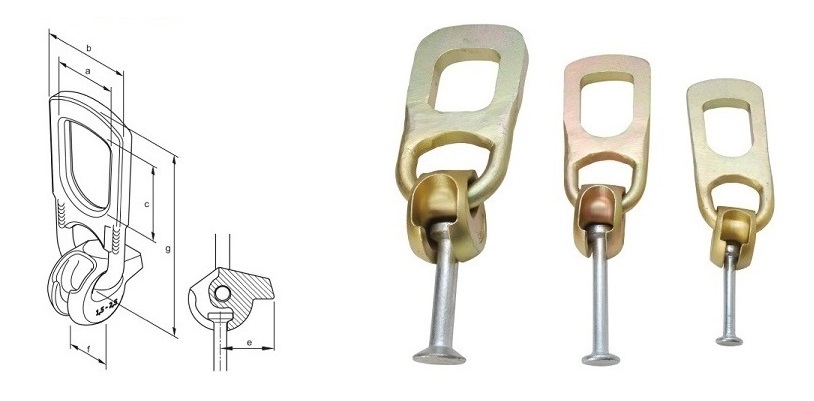

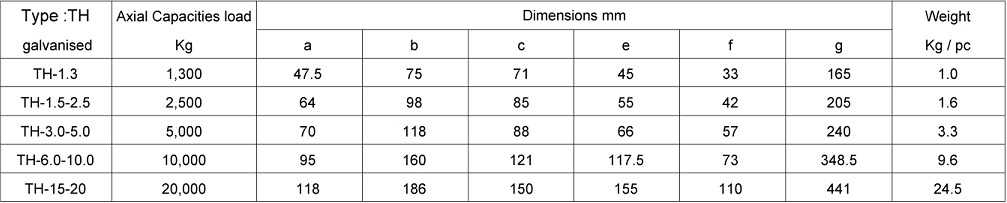

Lifting Clutch Type TH – Electro Plated

The capacity loads are axial with breakage safety factor equal to 5 for all types of lifting clutches (1,3 ton up to 32 ton). The Spherical Head Lifting Clutch comes in 6 different load groups. 1,3 to 32 ton, to suit the load carrying range of ALL TYPES OF LIFTING ANCHORS with spherical-heads.

Spherical Head Lifting Clutch – Tested for 3 x working load

Instructions for the use of Spherical Head Lifting Clutches

Lifting and Turning

The Spherical Head Lifting Clutch is constructed in a way that an unintended coupling off (even without tension by a lifting device) is impossible. On lifting, attention must be paid that the lip is in the direction of the tension being applied.

The Spherical Head Lifting Clutch is suitable for lifting in all directions (axial, diagonal, and lateral tension).

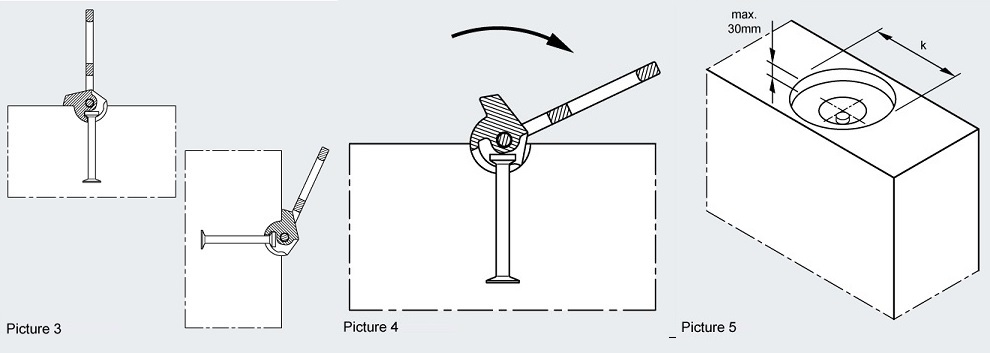

On turning of units, special attention must be paid to the lip position of the Spherical Lifting Head Clutch. The lip must always be in the be in the direction of the Tension (See picture 3).

Releasing the Spherical Head Lifting Clutch

To release the Spherical Head Lifting Clutch the tension on the clutch must be removed. Thereafter the Spherical Head Lifting Clutch can be released, by turning the handle in the opposite direction to the lip.

Corrosion Protection

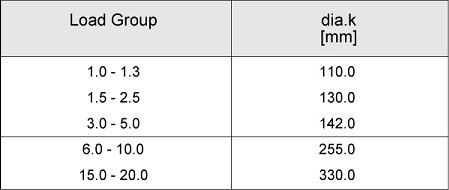

Corrosion protection can be increased by installing the Spherical Head Anchor in a sunken position. The recess former must be installed to ensure the functionality of the Spherical Head Anchor according to these installation instructions and must have the minimum dimentions in accordance with table 2 here below.

Dimensions for sunken assembly

The Spherical Head Lifting Clutch counts as a lifting device and is therefor subject to regular inspection (at least once a year – BGR 600 Section 2.8). This must be executed by an expert and it is the responsability of the user.

Particular safety procedures and regulations must be followed to extend the lifespan and durability of the Spherical Head Lifting Clutch. The right hook size and form should always be checked and be ensured.

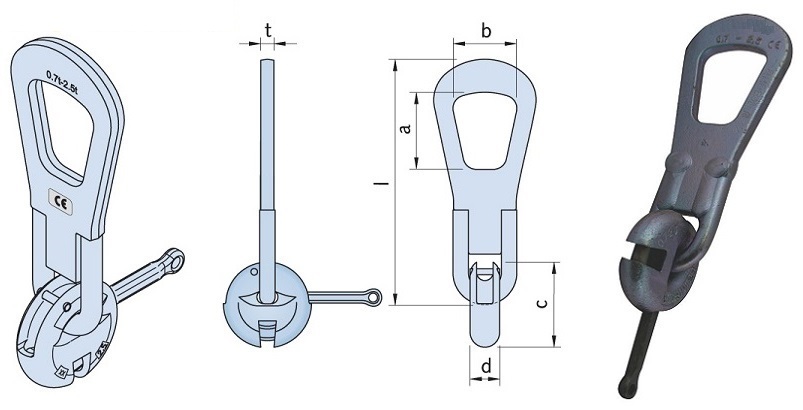

Ring Clutch TPA-R1 With Release Shackle

The ring clutch consists of a shackle and a clutch head. The shackle is free to move in any direction. The clutch head incorporates a locking bolt which fastens to the anchor. Anchors must be cast in with the correct recess former.

Ring Clutches are available in four load groups. There are three or four anchors in each load group.

Rebar, Mesh and Construction Supplies (Pty) Ltd is the largest supplier of accessories, tools and equipment for placing and fixing rebar in Africa. We also stock a wide range of accessories for the construction, scaffolding and formwork industries.

Lifting Clutches and Anchors Menu

RMCS Precast Lifting Anchor Ring Clutches

Click here to obtain more information about our Precast Lifting Anchor Ring Clutches?

RMCS Precast T-anchor Lifting Clutches

Click here to obtain more information about our Precast T-anchor Lifting Clutches?

RMCS Lifting Socket Lifting Loops

Click here to obtain more information about our Lifting Socket Lifting Loops?

RMCS Eye Bolts or Lifting Eyes

Click here to obtain more information about our Eye Bolts or Lifting Eyes

RMCS Swivel Lifting Eyes or Lifting Hoists

Click here to obtain more information about our Precast Swivel Lifting Eyes or Lifting Hoists?

Precast Socket Magnets

Click here to obtain more information about our range of Precast Socket Magnets?

RMCS Precast Erection Anchors

Click here to obtain more information about our Precast Erection Anchors?

RMCS Precast Two Hole Lifting Anchors

Click here to obtain more information about our Precast Two Hole Lifting Anchors?

RMCS Tilt-up Lifting Inserts

Click here to obtain more information about our Tilt-up Lifting Inserts?

RMCS Precast Type-T Lifting Anchors

Click here to obtain more information about our Precast Type-T Lifting Anchors?

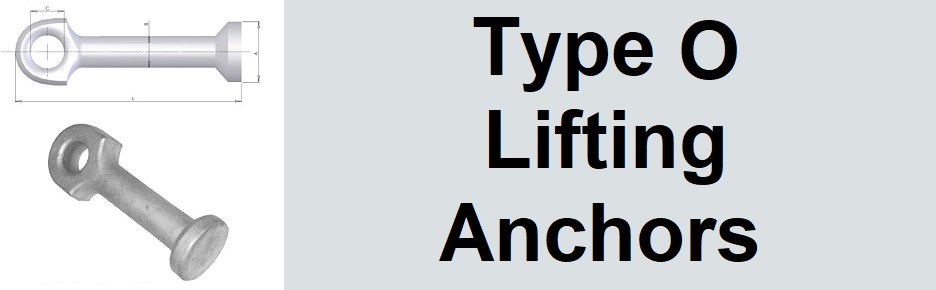

RMCS Precast Type-O Lifting Anchors

Click here to obtain more information about our Precast Type-O Lifting Anchors?

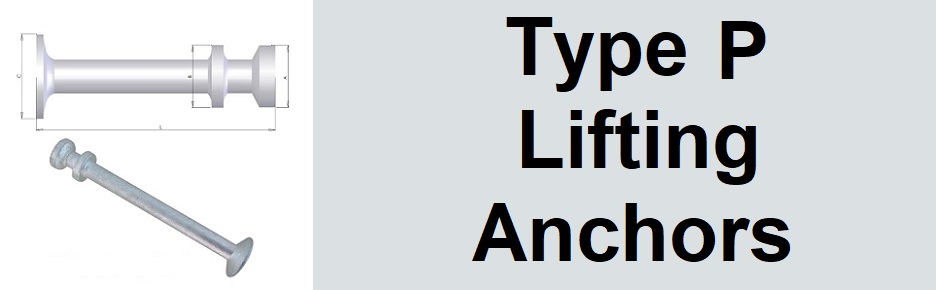

RMCS Precast Type-P Lifting Anchors

Click here to obtain more information about our Precast Type-P Lifting Anchors?

Watch a video of a successful project where RMCS Lifting Sockets and Lifting Eyes were used to install concrete elements

Take 30 seconds and watch the videos here below to get a quick insight of the range of products that manufacture or distribute?